INSULATED PANELS

Cold Storage Industrial & Commercial Metal Panels

Custom Built Cold Room Storage Warehouses and Large Facilities

Industrial panels are insulated panels specifically designed and constructed for use in the walls, ceilings, and floors of cold storage facilities and warehouses. They are an integral component in the structure of the building and play a crucial role in creating and maintaining controlled environments for the storage of temperature-sensitive goods. For more information call us at 800-321-2112.

Dade Industrial Panels are insulated metal panels composed steel skins laminated to a minimum of 1.6” polyisocyanurate foam core, PIR (minimum 2.3 pcf density) manufactured in the USA. Dade Cold Storage Panels are insulated panels specifically designed for walls, ceilings, and floors of cold storage facilities and essential for maintaining controlled environments for temperature-sensitive goods. Dade panels consist of metal skins laminated to a polyisocyanurate foam core and are vital for industrial preservation and refrigeration across a diverse range of industries.

#DADE DIFFERENCE

“Turn-key installation , from drawings, code compliance to completion. We even manufacture our own doors & hardware - one stop shop!”

Insulated Metal Panel Features and Benefits

Customized: Versatile for any configuration, able to provide a quote for any project no matter how big or small

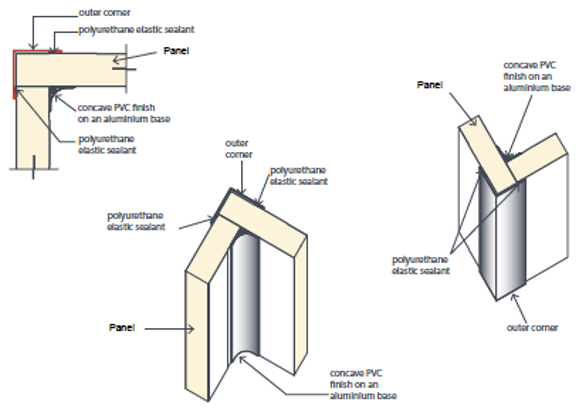

Quick Installation: Easy to maintain, interior rounded concave corners does not collect debris and easy to clean

Relocatable: Easily removable and configurable - wall, floor, corner and ceiling joints

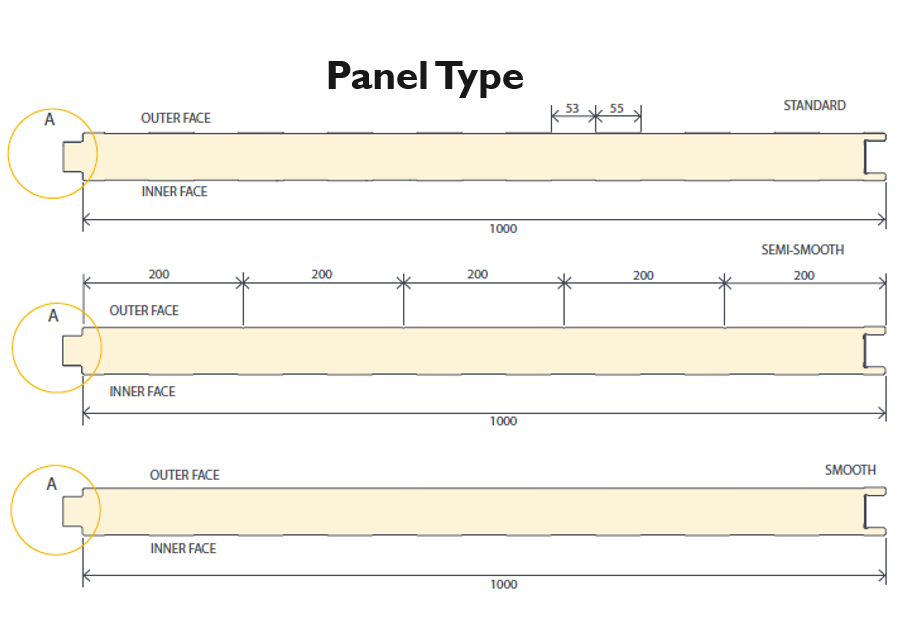

Cost-Efficient: Made to order, custom measure, avoids waste, up to 39 ft. panel length and usable width of 1000mm/39 3/8”

Durable: Resistant to harsh environmental elements, panel thickness from 1 9/16” up to 6” inches

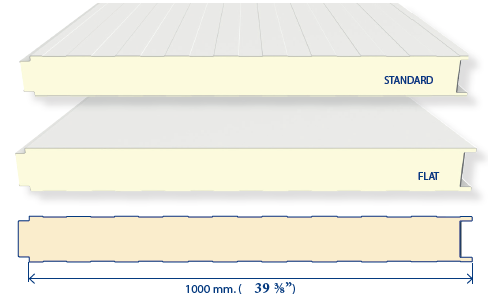

Aesthetics: Pleasing appearance, choice of finishes - standard or flat, optional panel thickness as well as coatings, doors and accessories

Insulation: High thermal insulation capacity, panel thickness choices ranging from 40mm/1 9/16” up to 150mm/6”

Safe & Tested: Mechanically strong, fire tested (ASTM E 84) and strength tested (STEM E 8) for optimal & safe performance

Stability: Dimensionally stable, up to 39 ft. in panel length and usable width of 1000mm/39 3/8”

Seal: Water vapor tight, minimum 2.3 pcf density of 1.6” polyisocyanurate foam core, R Value is 35.5

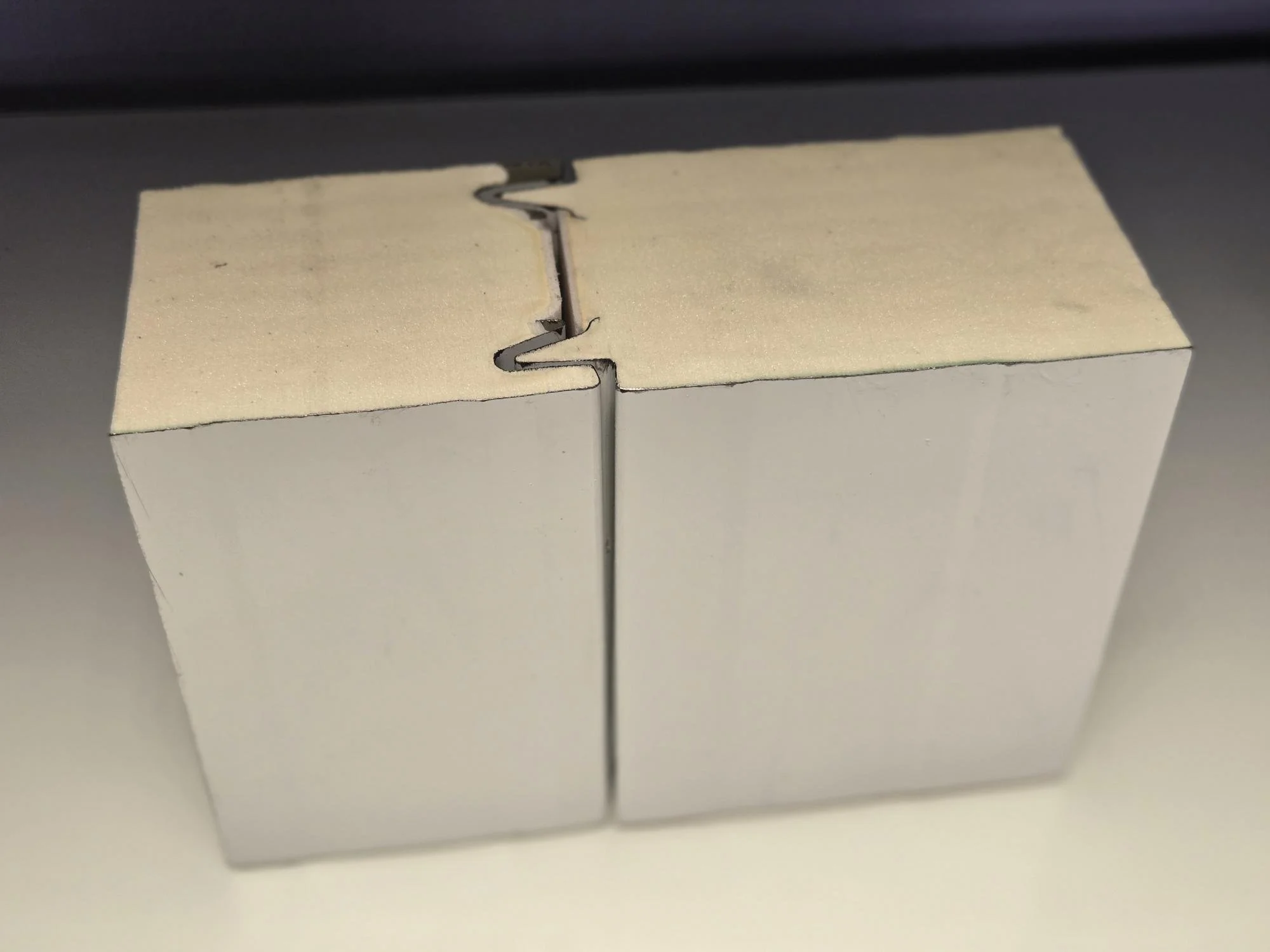

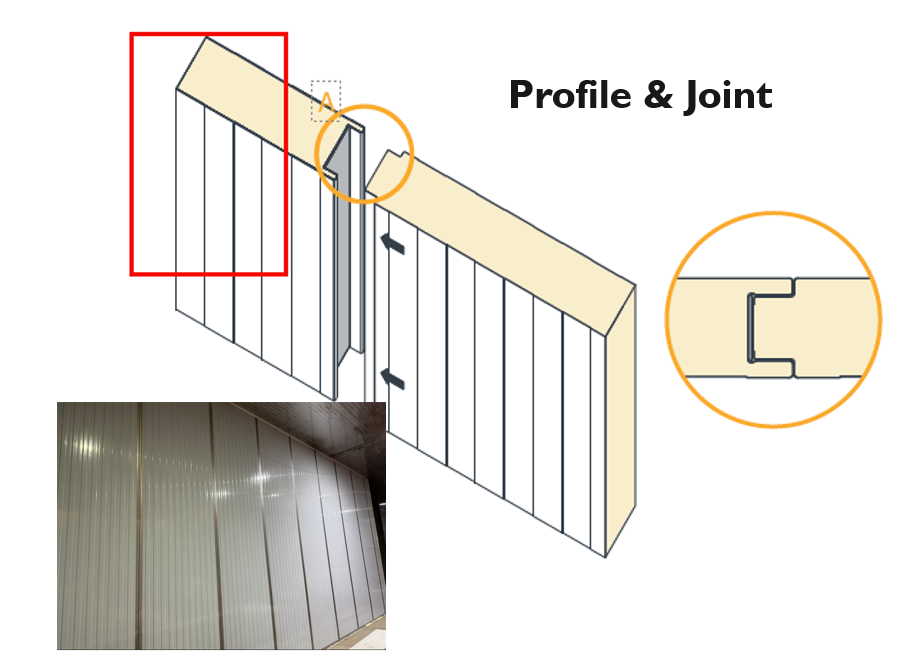

Pre-engineering panels: Air-tight channel tooling optimizes cold storage solutions

Chrome plated hardware: Durable finish enhances corrosion resistance for longevity in extreme conditions

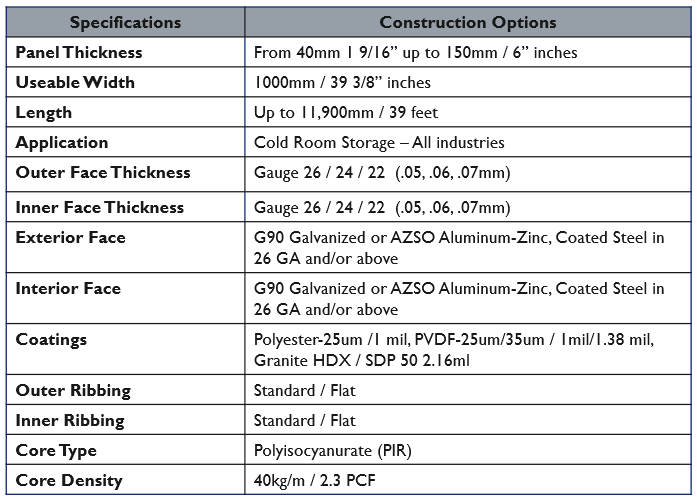

Insulated Panel Technical Data

Warranty information

1 year warranty on hardware components.

10-year warranty on panel construction. (NOTE: Does not include labor)

50-year warranty on foam insulation.

Marketing Resources - Literature

Click on the active links to download

Insulated Metal Panels

Manufactured of steel outer layers bonded to a minimum 1.6-inch polyisocyanurate foam core with a density of at least 2.3 pcf and a length of 39 ⅜ inches (1000 mm).

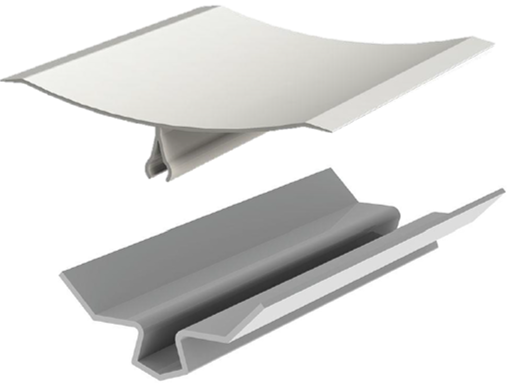

The tongue and groove design permits panels to be suitable for refrigeration projects, especially in the Agro-food sector for transporting and storing frozen foods.

Available in (7) seven thicknesses and (2) two exterior finishes and various custom doors.

3 Types of Metal Panels

Standard, Semi-Smooth and Smooth

Why The Need for Industrial Insulated Panels?

Innovative industrial panel designs enhance temperature control and energy efficiency, improving cold storage performance. A durable coating protects against wear, moisture, chemicals, and abrasion in demanding environments. Chrome-plated parts offer longevity with a corrosion-resistant finish. The hardware ensures functional reliability, supporting heavy loads and enduring rigorous use.

What makes Dade Industrial Panels different? #DadeDifference

All Dade Engineering products undergo thorough testing at our advanced manufacturing facilities to ensure accuracy and reliability before they are pre-assembled and shipped.

Installation diagrams are conveniently attached to every cooler, and each panel is clearly labeled for easy identification during setup.

We utilize high-quality resources to create airtight sealed panels, ensuring optimal performance.

Our dedicated team is always ready to assist you throughout your customized project, providing support from engineered plans, initial site surveys, through obtaining necessary permits, to complying with relevant codes and inspections.

Safety - UL, UL7, EISA & NSF approved.

What Options and Accessories are Available?

Optional Doors & Accessories: High Speed Doors, Heaters, Bumpers & Ceilings

State of Art Controls: Temperature reading controls, effective door alarms and reliable light monitors are available and work together to provide an optimal storage environment for your perishable goods, enhancing both safety and efficiency.

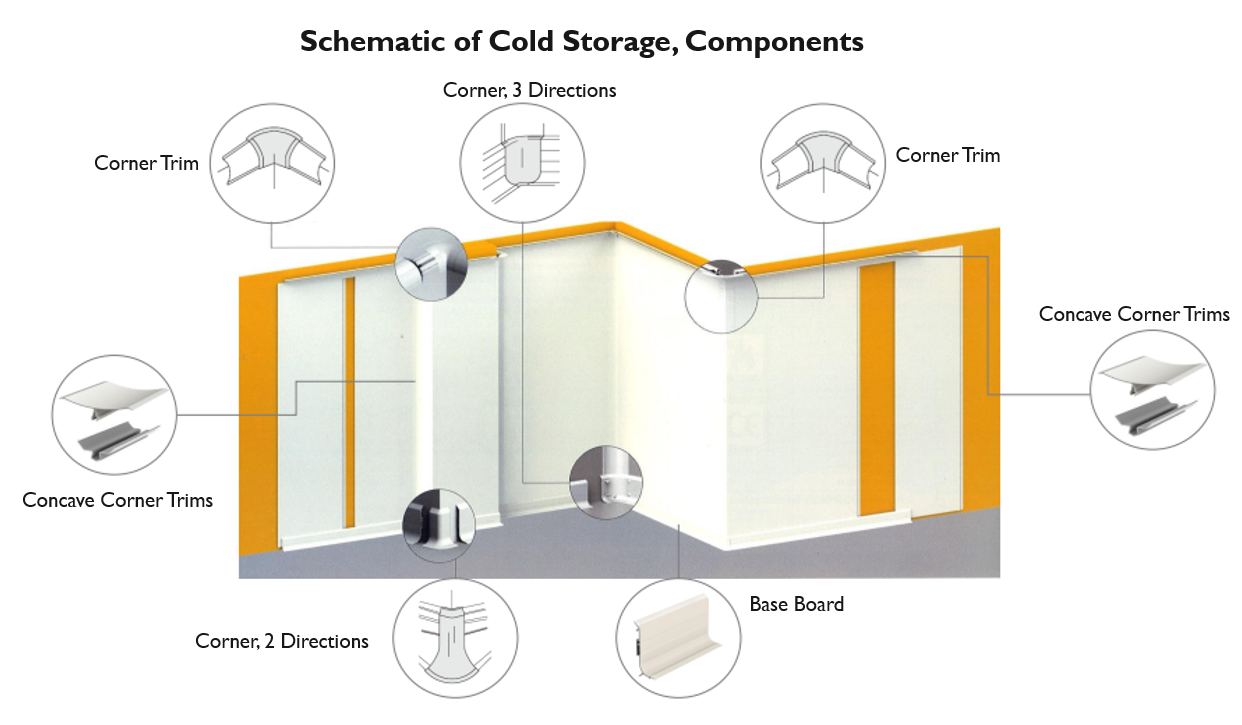

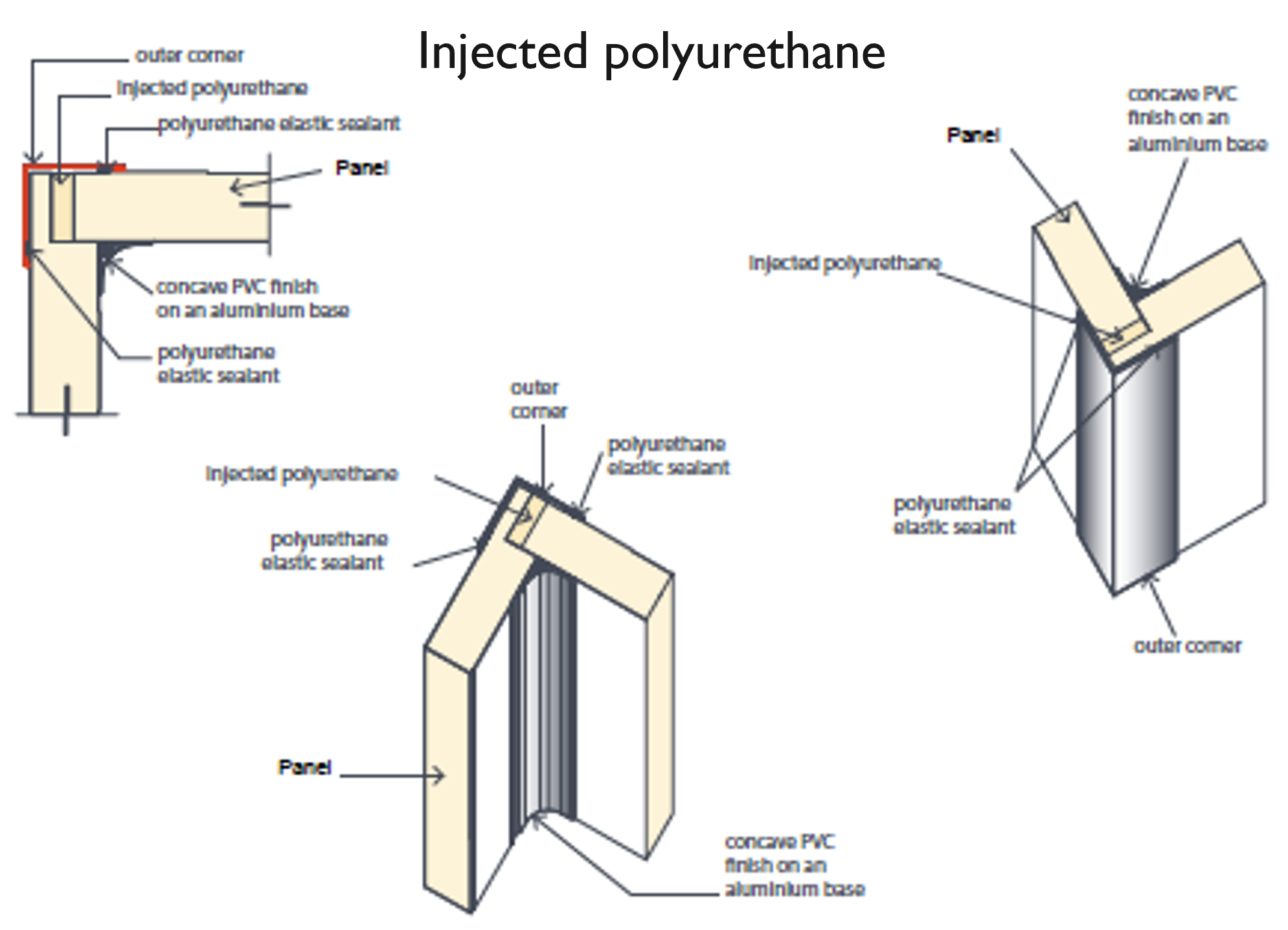

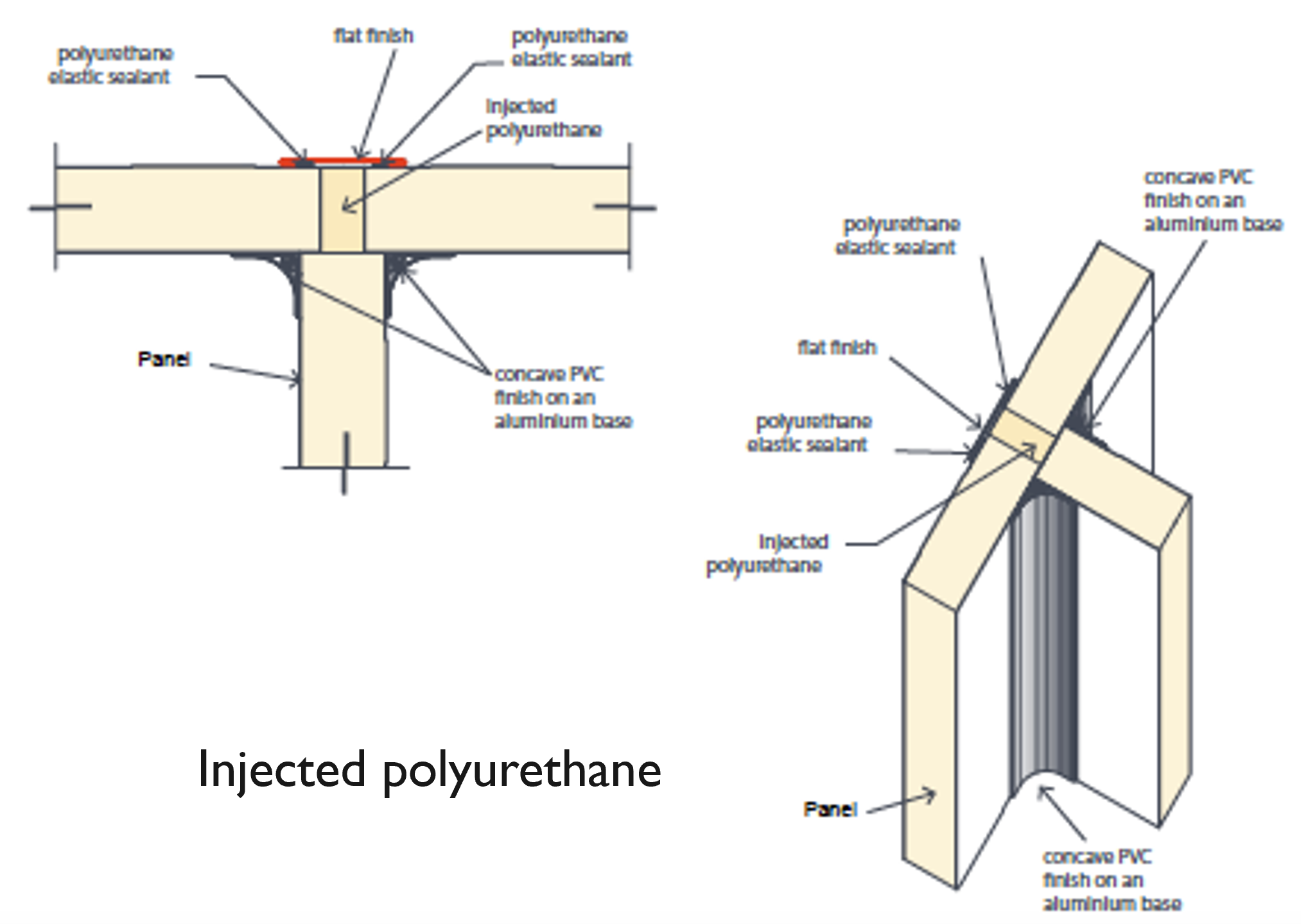

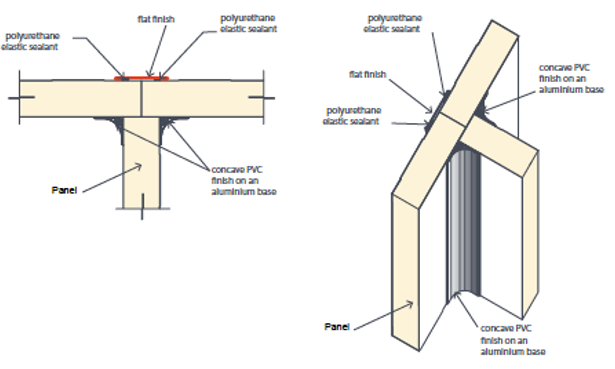

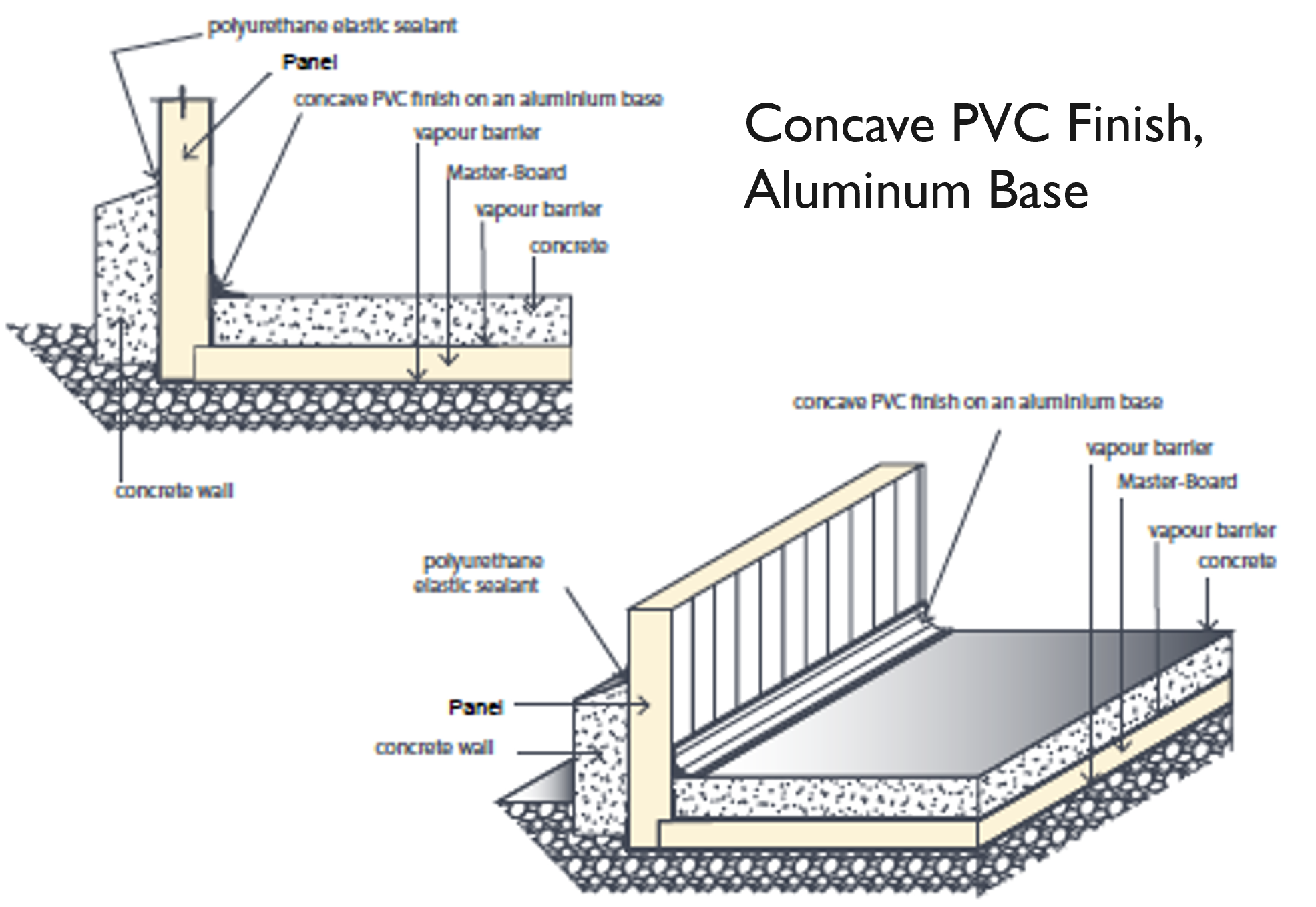

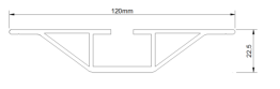

Panel & Corner Joint Construction for Cold Storage

Single and Double Joints, also available in Triple (3 joints)

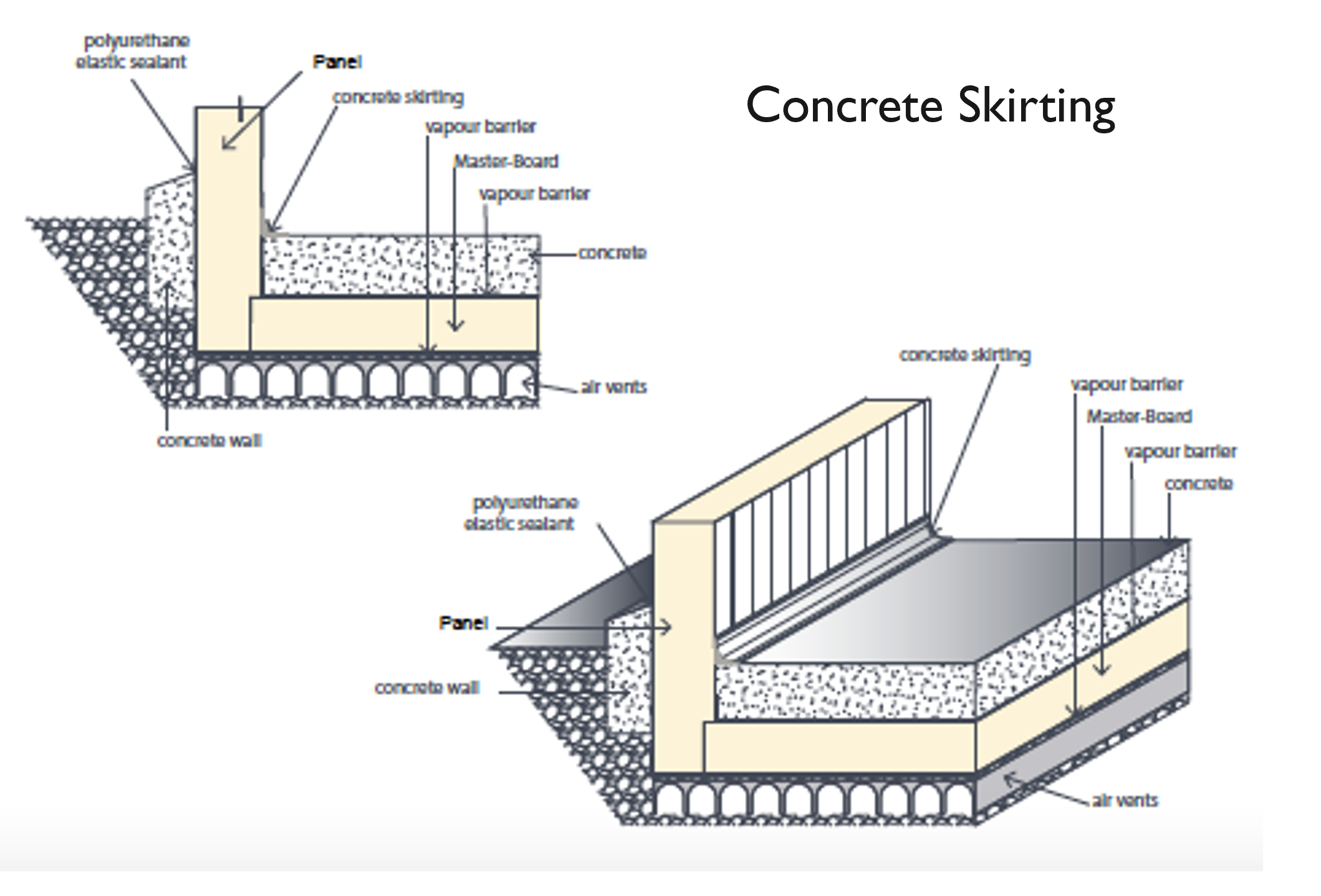

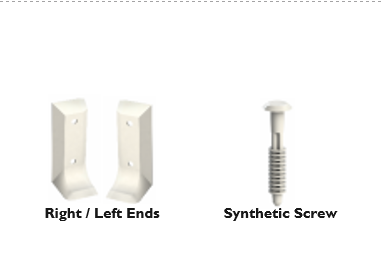

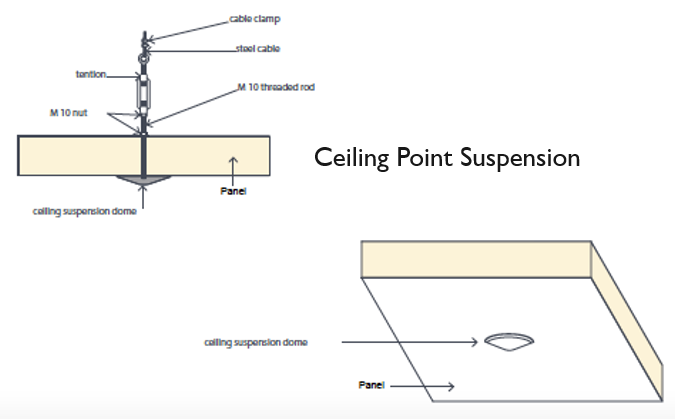

Insulated Floor System & Base Board Accessories for Cold Storage

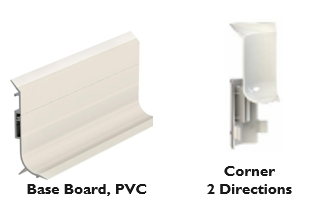

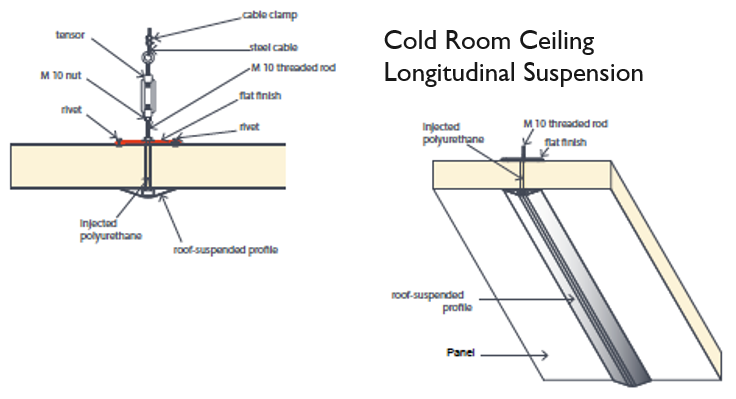

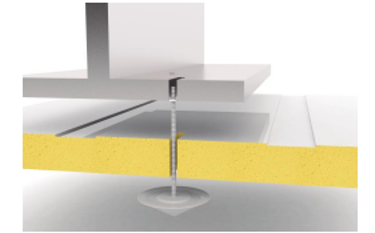

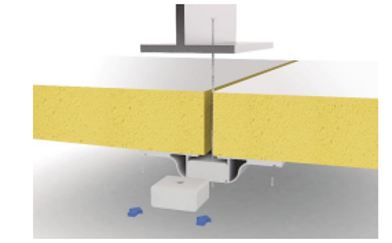

Hanging Ceiling Systems for Cold Storage

Choose from two different ceiling systems: Longitudinal Suspension or Ceiling Point Suspension

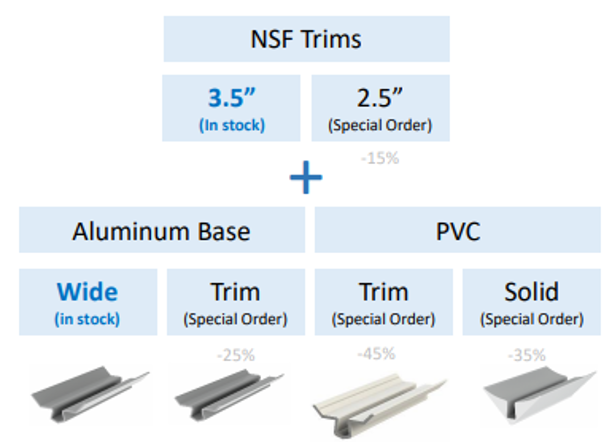

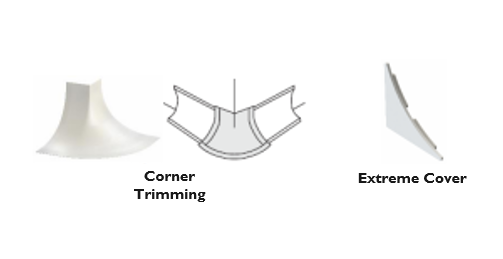

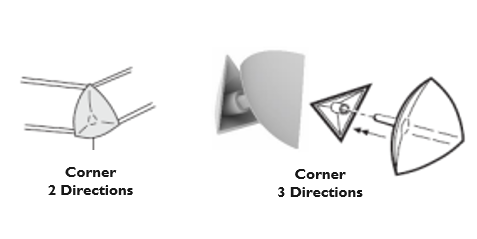

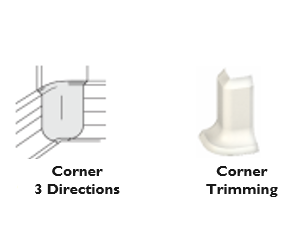

Corner Molding Systems

Aluminum and PVC Trims & Accessories